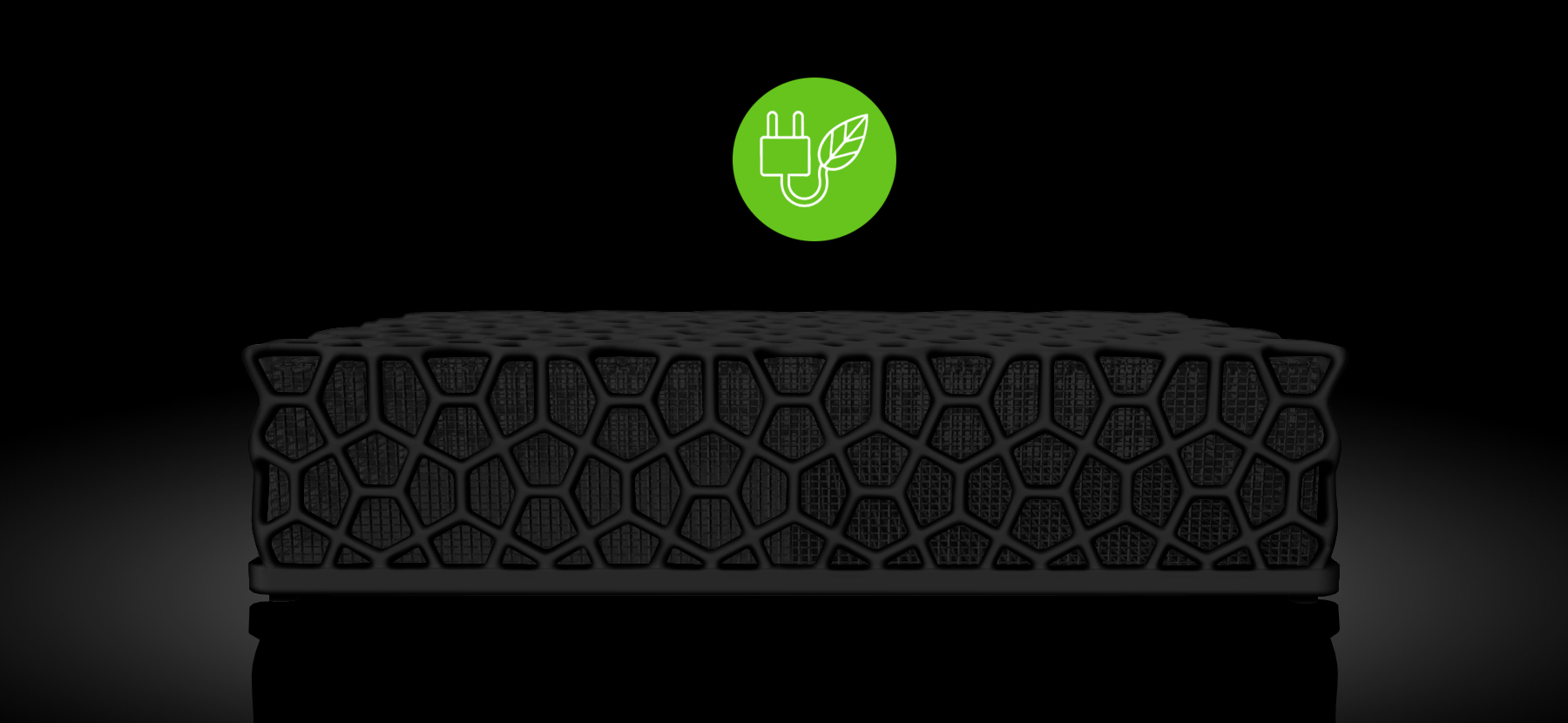

Even the most energy efficient home is likely wasting energy every minute of every day. There are a massive amount of small devices that never turn completely off or when on hardly ever use electricity efficiently.

By themselves these devices will not cause a huge increase in energy consumption. But if you add all devices together, they are often responsible for adding 10 percent or more to your monthly utility bill. With the average American household owning 25 consumer electronic devices, small usage can become a big chunk of your energy consumption.

Consumer external desktop hard drives are some of the small devices people use frequently. These hard drives produce an extreme amount of heat that needs to be dissipated. Sometimes fans are used but can be expensive and consume even more electricity. We wanted to use the natural cooling process of venting in order to eliminate the fan completely and create a unique signature look. The problem with venting is that it can look industrial,expected, or thrown on as an afterthought.

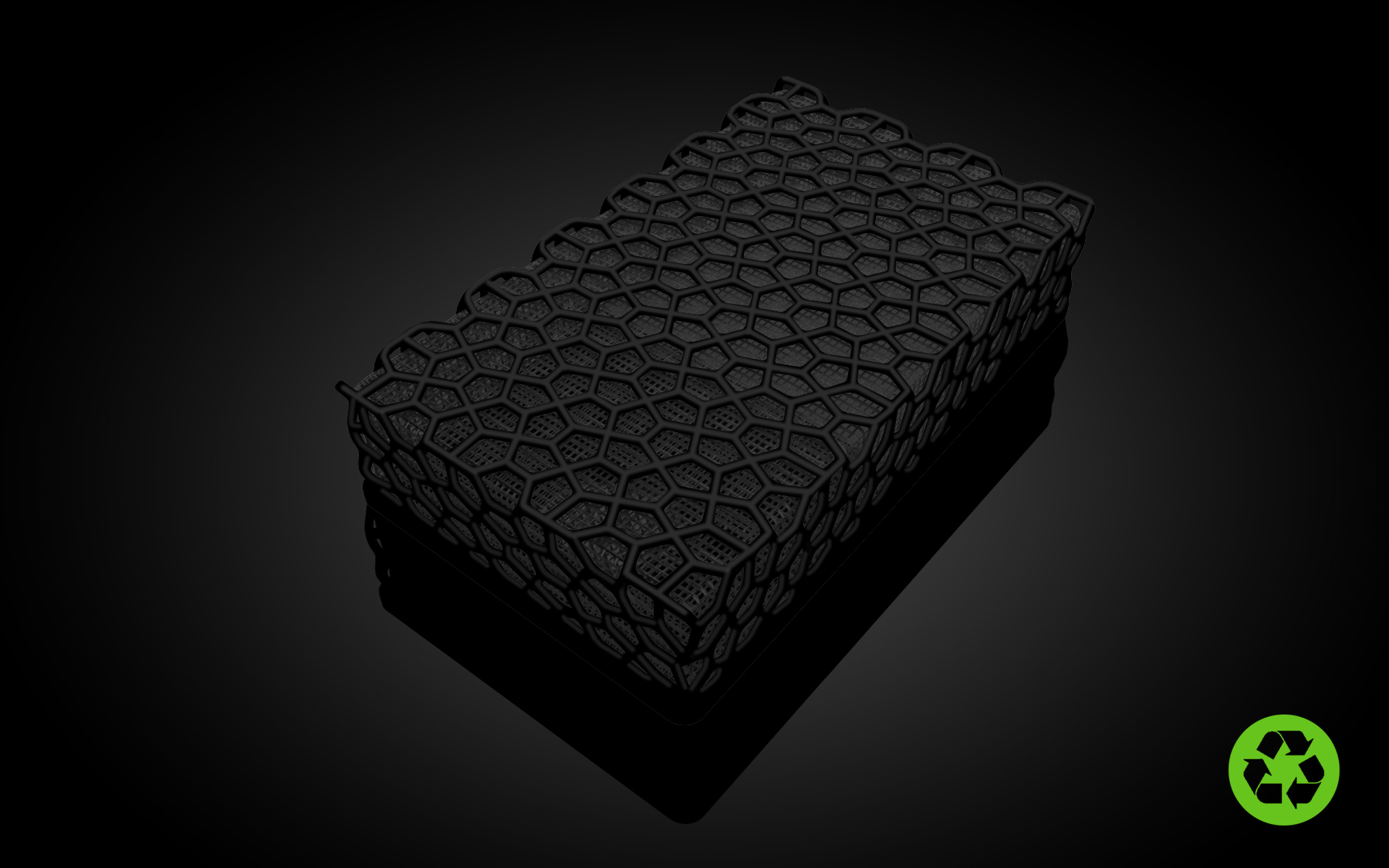

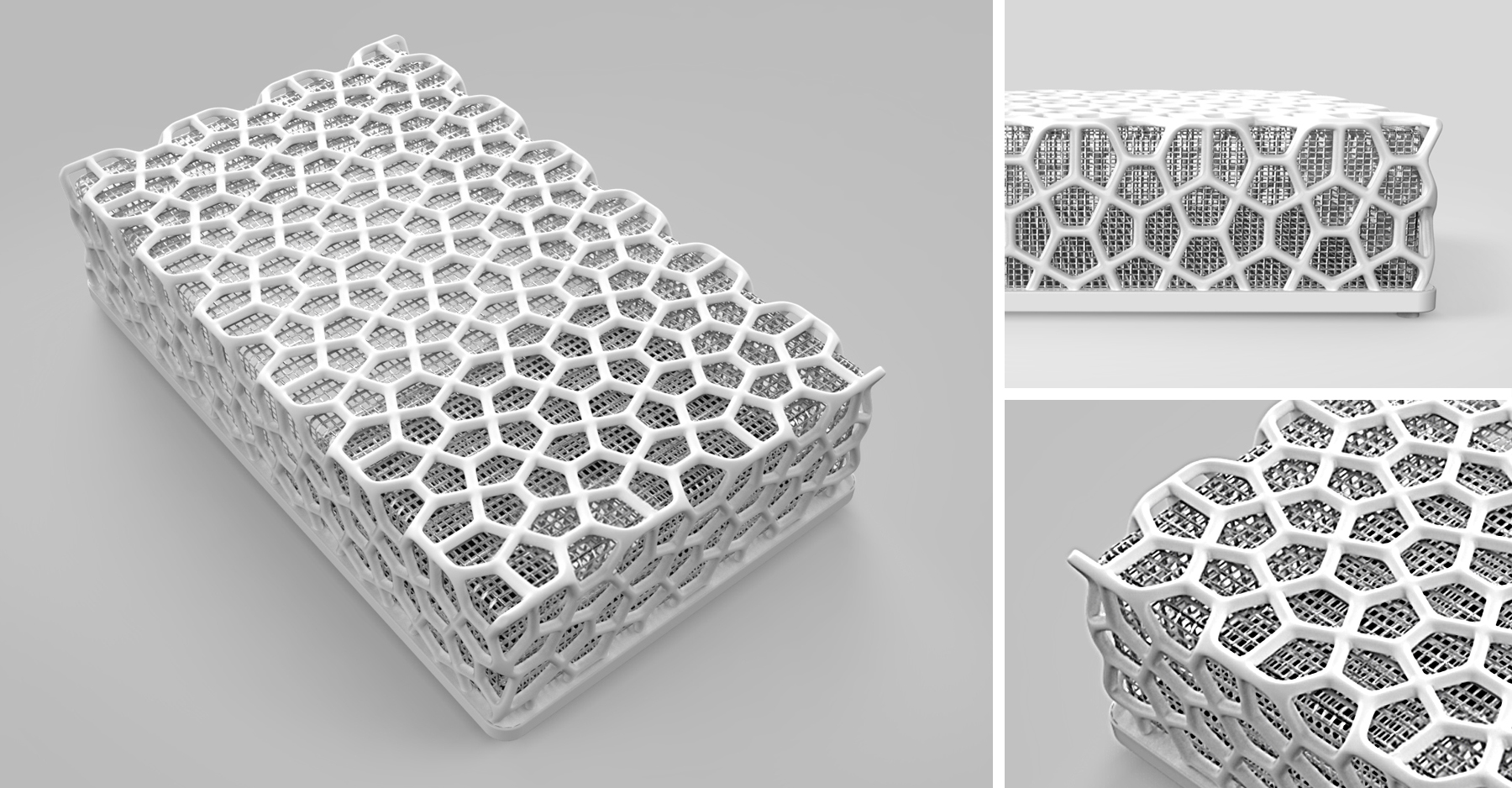

Looking to blend energy saving techniques with renewable resources, Ashcraft Design focused on the incredible amount of waste produced by tires thrown away every year. Less than 40% of tire waste is recycled every year. Not nearly enough is recycled to catch up to the alarming amount of tire waste each year. Though use of recycled tires in general is not new, application of recycled tires in the consumer electronics industry is relatively new. The inherent properties of rubber make them perfect for use throughout external hard drives. Recycled rubber provides high abrasion resistance, excellent shock resistance to protect the hard drive from impact, extremely tactile surface to grip, and has less build up to heat created by the hard drive. We wanted to use these properties to our advantage and create an organic exoskeleton that wraps around the entire hard drive, bringing the internals outside without making it look like an unfinished product. The venting is now used as the major design element, creating a beautiful exoskeleton of silky rubber that protects and encases the hard drive while creating the maximum amount of airflow needed to eliminate the fan and decrease the amount of energy consumed.

Multiple colorways would be created of just the exoskeleton and sold as “skins” that wrap around the hard drive enclosure. This gives the consumer multiple options to personalize their hard drive without having to buy a brand new drive.

While still only in the conceptual phase this product is yet to be made. Here at Ashcraft we love to share some of the thinking that goes on in our studio to help better our community and our environment through the use of design.